Yanmar extends its engine line up to 155 kW

|

DOWNLOAD PRESS RELEASE |

|

|

|

|

DOWNLOAD HERE THE HIGH RESOLUTION PICTURES

Yanmar extends its engine line up to 155 kW

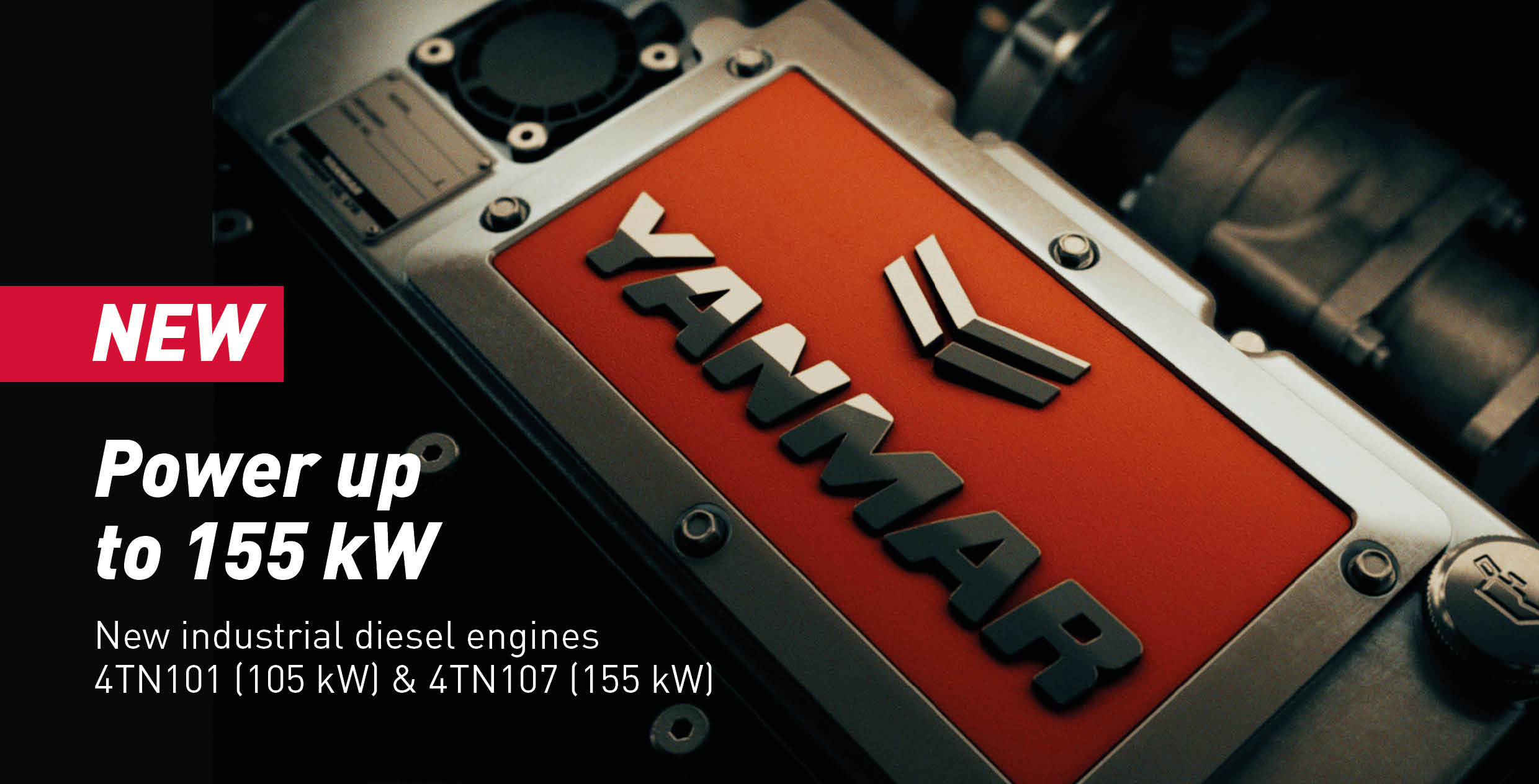

Yanmar has selected the Intermat exhibition to launch its most impressive lineup development for 20 years. Not just one, but two brand new engine families will be officially introduced at the show, extending Yanmar’s current power range up to 155 kW. The engines can be seen on the Yanmar stand E46 in Hall 5A.

Yanmar has selected the Intermat exhibition to launch its most impressive lineup development for 20 years. Not just one, but two brand new engine families will be officially introduced at the show, extending Yanmar’s current power range up to 155 kW. The engines can be seen on the Yanmar stand E46 in Hall 5A.

The smaller one is a 3.8L displacement engine, named 4TN101, which lines up in the 55 to 105 kW power range with torque up to 550 Nm.

The bigger one, called 4TN107, has a 4.6L displacement with power ratings ranging from 90 to 155 kW and torque exceeding 805 Nm.

Both engines feature a Common Rail injection system, full authority electronics and after-cooled turbocharging (with a two stage turbo on the 4TN107 upper ratings). Specific power and torque are among the highest available in the market.

Both engines feature a Common Rail injection system, full authority electronics and after-cooled turbocharging (with a two stage turbo on the 4TN107 upper ratings). Specific power and torque are among the highest available in the market.

Both engine families will be EU Stage V-certified and share the same design target of reducing the Total Cost of Ownership. Yanmar engineers’ efforts were therefore focused on setting new fuel economy targets, leveraging Yanmar’s extensive know-how in combustion process optimisation gained through its encompassing experience in diesel engines for industrial equipment and marine vessels. Curbing lube oil consumption was another key design target, achieved thanks to a state-of-the-art high precision manufacturing process developed specifically for this purpose.

The after-treatment system consists of EGR and separate DPF and SCR to safeguard durability and ensure uncompromising exhaust gas cleaning performance. Smaller, separate after-treatment modules also allow for easier installation.

Superior durability and robustness on one side and compactness and high power & torque density on the other have been jointly achieved to fulfil the requirements of the designated applications, i.e. construction, materials handling and agriculture.

With the introduction of these two new engine families 4TN101 & 4TN107 Yanmar brings its world-renowned reliability and overall top quality to a further extent. Leveraging on its leadership in supplying the free market, Yanmar now extends its success story to a greater power range.

Production is planned to start from the beginning of 2019 onwards.

More information can be found on: www.yanmarpowerup.eu

About Yanmar

With beginnings in Osaka, Japan in 1912, Yanmar was the first ever to succeed in making a compact diesel engine of a practical size in 1933. Moving on, with industrial diesel engines as the cornerstone of the enterprise, Yanmar has continued to expand its product range, services, and expertise to deliver total solutions as an industrial equipment manufacturer. As a provider of small and large engines, agricultural machinery and facilities, construction equipment, energy systems, marine, machine tools, and components — Yanmar’s global business operations span seven domains.

On land, at sea, and in the city, Yanmar’s Mission of “providing sustainable solutions focused on the challenges customers face, in food production and harnessing power, thereby enriching people’s lives for all our tomorrows,” stands testament to Yanmar’s determination to providing us with “A Sustainable Future.” For more information, visit us at https://www.yanmar.com/eu/About-Us/